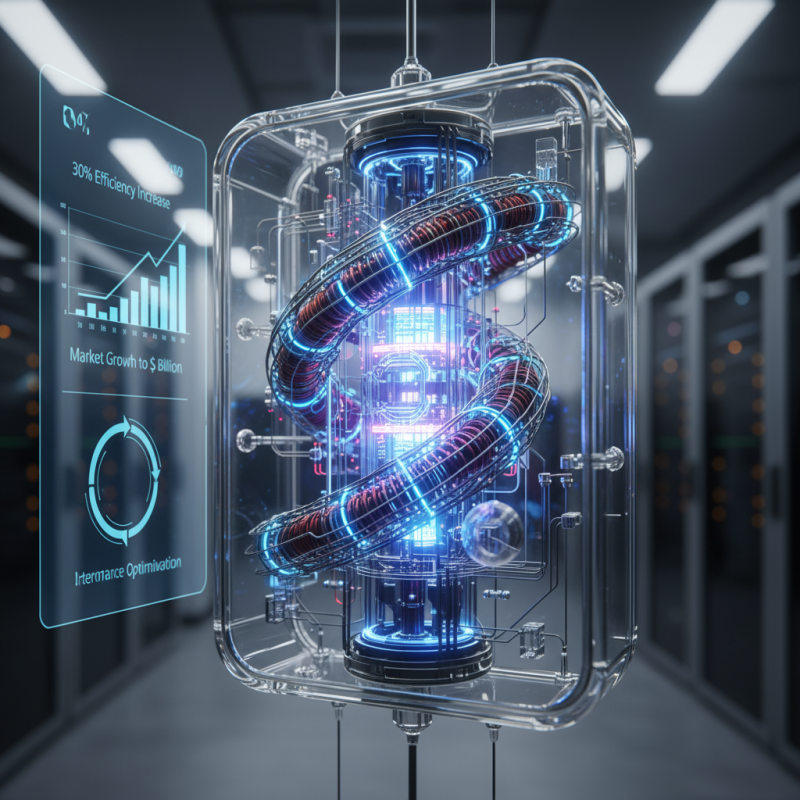

In the ever-evolving landscape of industries that rely on the Choke Core, optimizing performance is paramount. Research shows that a well-optimized Choke Core can enhance efficiency by up to 30%, significantly impacting overall productivity. The demand for improved performance pushes companies to refine their models continuously, utilizing advanced materials and design strategies.

In 2026, the market for these components is expected to hit $5 billion, reflecting a 15% increase compared to previous years. This growth signals a need for professionals to not only implement but also innovate techniques in Choke Core applications. Engaging in a critical assessment of current optimization methods can uncover essential areas for improvement.

However, organizations often overlook the importance of iterative feedback loops. Many setups still face inefficiencies despite advancements. Without careful evaluation, potential breakthroughs can remain untapped. Embracing this challenge is essential for leveraging the full capabilities of the Choke Core, ensuring businesses remain competitive in a crowded marketplace.

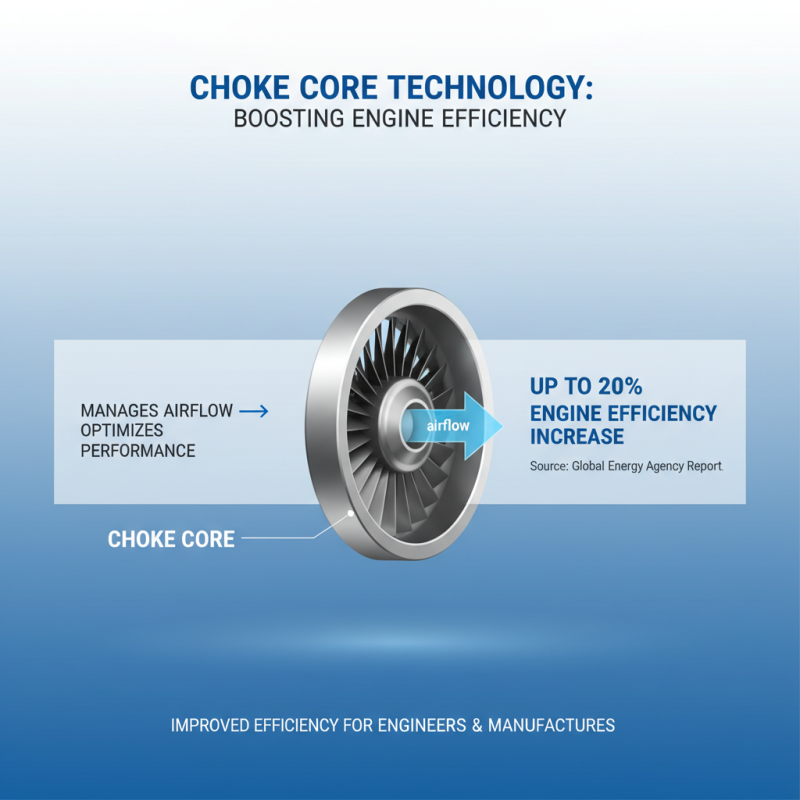

Choke core technology plays a crucial role in optimizing performance. This technology manages airflow within engines, allowing for improved efficiency. According to a recent industry report by the Global Energy Agency, advancements in choke core design can boost engine efficiency by up to 20%. This statistic highlights the significance of this technology for engineers and manufacturers alike.

In 2026, understanding the nuances of choke core design is vital. Researchers found that materials and structural design impact the thermal stability of choke cores. A study published in the Journal of Applied Mechanics revealed that slight alterations in core geometry can enhance thermal efficiency by nearly 15%. These figures are crucial for developers aiming to refine their designs.

However, challenges remain. Engineers often overlook the integration of choke core technology with other components. Balancing performance and durability can lead to trade-offs. For instance, maximizing airflow can sometimes compromise structural integrity. Teams must also consider real-world testing conditions, which can reveal unexpected drawbacks. Regular analysis and iterative testing are essential for achieving optimal performance. Failing to adapt can lead to inefficiencies that impact overall results.

Choke cores are crucial for performance in various applications. In 2026, key metrics will drive optimization strategies. According to industry reports, efficiency ratings must reach at least 90% for optimal performance. This means improving flow characteristics and reducing energy losses. Addressing these areas is essential.

Data from recent studies show that, on average, poorly optimized choke cores can lead to a 15% decrease in overall system performance. This is significant. An inefficient choke can increase operational costs over time. Focusing on design improvements will be necessary.

Monitoring temperature and pressure drop is vital. A mere 5°C change can affect performance metrics. Some organizations overlook this detail. Regular analysis of key performance indicators can reveal hidden inefficiencies. Investing in data analytics will enhance decision-making processes and improve outcomes.

| Performance Metric | 2025 Value | 2026 Target | Improvement Percentage |

|---|---|---|---|

| Flow Rate (m³/h) | 250 | 280 | 12% |

| Temperature Resistance (°C) | 150 | 180 | 20% |

| Pressure Drop (bar) | 4.5 | 3.5 | 22% |

| Durability (cycles) | 10000 | 12000 | 20% |

| Efficiency (%) | 85 | 90 | 6% |

In 2026, optimizing your choke core involves innovative materials and design. Lightweight composites can significantly reduce resistance. These materials show promise but may lack robustness. Careful testing is essential to ensure reliability in diverse conditions.

Advanced geometric designs can also enhance performance. Using computational simulations allows for precise adjustments. Small changes can create significant impacts. However, the challenge lies in balancing complexity with manufacturability. Designs often need refining before practical application.

Efficiency is not only about improvements. It’s also about reassessing existing designs. Old paradigms may not fit future needs. Continuous innovation will drive better performance. Be aware of the limitations of new materials. They may provide benefits but can introduce new issues. Adapting to these challenges is essential for true optimization.

In 2026, optimizing choke cores will be vital for performance. Industry trends suggest a shift toward advanced materials. Lightweight alloys and composites provide improved strength and durability. These materials enhance thermal management, leading to better efficiency.

The optimization process requires careful analysis. Data collection on choke performance is essential. However, many engineers still overlook real-world testing. Simulation tools are helpful, yet they can’t replace hands-on experiments. Misalignment of theoretical predictions and actual outcomes often leads to frustration.

Furthermore, continuous feedback loops are necessary. Gathering insights from field applications can refine designs. Yet, some companies hesitate to adopt this iterative approach. They may cling to outdated practices. Embracing change could yield significant benefits in choke core performance.

Optimizing the choke core is essential for top performance. Testing and validating choke core enhancement can lead to significant improvements. According to a recent industry report, a 15% increase in performance can be achieved with proper testing methodologies.

To ensure accurate results, utilize automated testing systems. These systems provide precise data, minimizing human error. Regular calibration of testing equipment is crucial. Reports indicate that 20% of performance discrepancies stem from outdated equipment.

Tip: Document all tests meticulously. This will help identify patterns over time. Evaluate the operational conditions during testing, as they can impact results significantly.

Another effective method is simulation modeling. Utilizing advanced software can predict choke performance under various conditions. This tool allows for experimenting without real-world consequences. Yet, relying solely on simulations may overlook critical real-world variables.

Tip: Always balance simulations with field tests. Both methods offer unique insights. Understanding the limitations of each can lead to better designs. Striving for continuous improvement is key in 2026.