Determining the correct amperage for a transformer is essential in various electrical applications. According to industry expert Dr. John Smith, "Understanding amperage ratings can make or break a project." The amperage transformer is a critical component in managing electrical loads efficiently.

Accurate calculations can prevent overheating and potential damage. Many technicians overlook these details, leading to costly mistakes. A true understanding of the transformer’s capacity is vital for reliable performance. The challenge often lies in balancing safety and functionality.

A deep dive into the specifics reveals that different transformers have unique amperage requirements. Factors like voltage, phase, and frequency play significant roles. Engineers must consider these aspects meticulously. Errors in judgment can result in failure or damage. Knowledge and experience in the amperage transformer realm can greatly enhance project outcomes.

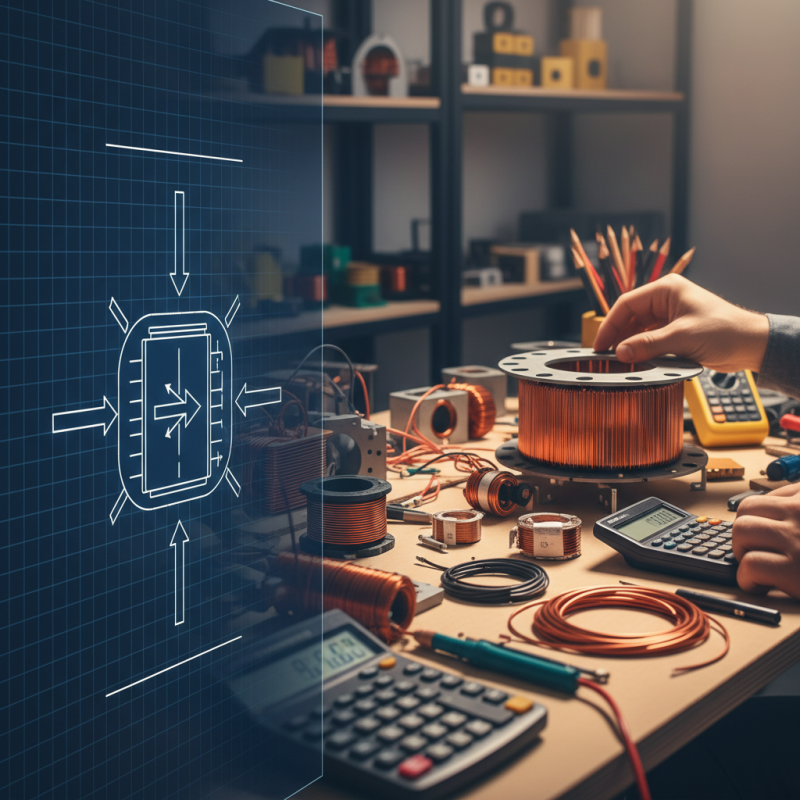

When considering transformer basics, understanding amperage is crucial. Amperage indicates the current capacity. A transformer has primary and secondary coils. The relationship between voltage and current in these coils allows for efficient power distribution. A step-down transformer reduces voltage, but it increases amperage. Conversely, a step-up transformer does the opposite.

Calculating amperage involves several factors. It requires knowing the power rating in watts and the voltage. The formula is simple: Amperage = Power (Watts) / Voltage (Volts). For instance, if a transformer handles 1000 watts at 120 volts, the amperage is about 8.33. It’s essential to ensure that your calculation aligns with the expected load. Sometimes, miscalculations can lead to overheating or damage.

Transformer applications vary widely. They can be used in residential, commercial, and industrial settings. Understanding the specific needs of your system is vital. People often overlook their actual power requirements. This can lead to using transformers that are either overqualified or underqualified. Evaluate your needs carefully to avoid potential issues down the road.

| Transformer Type | Voltage (V) | Power (kVA) | Calculated Amperage (A) |

|---|---|---|---|

| Step-Down Transformer | 240 | 5 | 25 |

| Step-Up Transformer | 120 | 10 | 83.33 |

| Isolation Transformer | 480 | 15 | 18.75 |

| Auto Transformer | 600 | 20 | 33.33 |

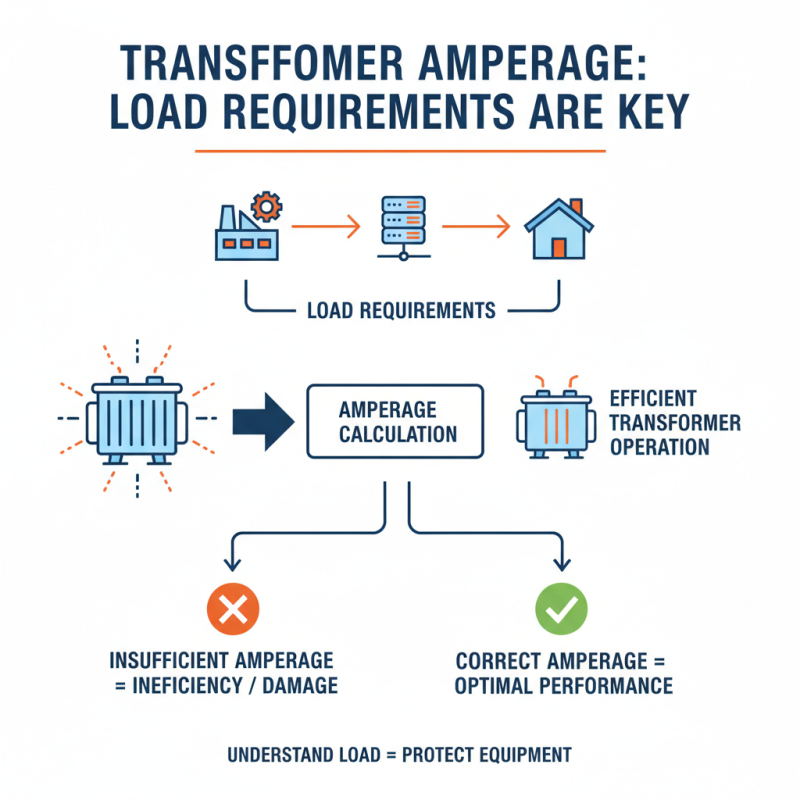

When determining the amperage for a transformer, load requirements play a crucial role. These requirements reflect how much current the load devices need to function efficiently. A poor understanding of this can lead to inadequate amperage calculations. This oversight can result in transformer inefficiency or, worse, damage.

Accurate amperage determination considers both continuous and peak loads. Continuous loads run all the time, while peak loads may only occur intermittently. Not all devices have the same load characteristics. For example, a motor may draw more current at startup than during normal operation. Failing to account for this could lead to choosing a transformer with inadequate capacity.

Furthermore, loads can change over time. Seasonal variations, equipment upgrades, and operational shifts can influence amperage needs. A transformer rated for current demands today may not suffice tomorrow. Regular assessment of load requirements ensures that the transformer meets these evolving needs, enhancing performance and reliability. Ignoring this can cost you in the long run, both in resources and system integrity.

Determining the amperage of a transformer involves understanding its primary and secondary voltage ratings. To calculate the primary amperage, use the formula: Amperage = Power (Watts) / Voltage (Volts). For instance, if a transformer operates at 10,000 Watts on a primary voltage of 240 Volts, the primary amperage would be approximately 41.67 Amps.

On the secondary side, the calculation is similar. The secondary amperage calculation is based on the transformer's turns ratio. If the secondary voltage is 120 Volts, you can apply the same power calculation. For the previous example, the secondary amperage would be 83.33 Amps. This demonstrates how voltage ratings dramatically influence amperage.

Working with these ratings requires precision. Small errors in voltage measurement can lead to significant discrepancies in amperage calculations. Recent industry reports indicate that miscalculating these values by even 10% can disrupt operational efficiency by 15%. Hence, careful measurement and calculation practices are essential for effective transformer operation.

The power factor is a critical element affecting the amperage in transformer applications. It measures how effectively incoming power is converted into useful work output. A low power factor indicates that a larger amount of current is needed to produce the same output. For example, if the power factor is 0.8, the current drawn can be significantly higher than when the power factor is 1.0. Data from the Energy Information Administration suggests that improving power factor can reduce energy losses by as much as 10-15%.

In transformer applications, this translates to notable financial implications. Increased amperage due to a poor power factor can lead to overheating. Transformers can operate inefficiently, causing additional wear and potentially shortening their lifespan. According to industry reports, poor power factors increase energy costs by up to 30% due to higher demand charges. Maintaining an optimal power factor is essential, but achieving and sustaining this can be complex.

It’s crucial to monitor both current and voltage for optimal performance. Many operators overlook this aspect. Ignoring the effects of power factor can complicate the complexity of a system, creating unnecessary challenges. A deliberate reflection on power factor management can lead to improved efficiency and cost savings in transformer operations.

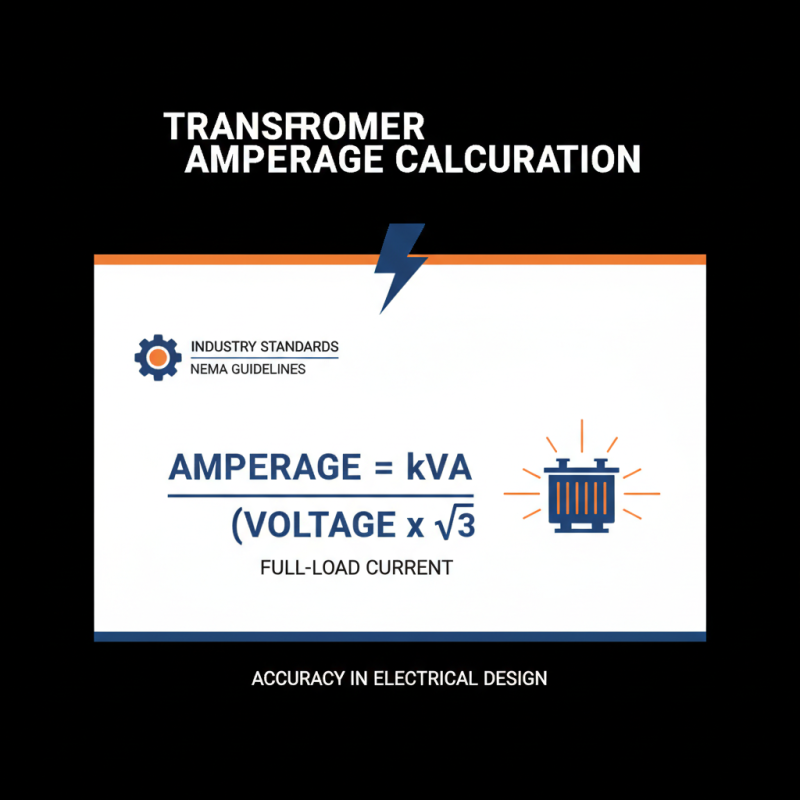

When determining the amperage for a transformer, industry standards are crucial. The National Electrical Manufacturers Association (NEMA) provides guidelines for transformer ratings. NEMA suggests calculating the full-load current using the formula: Amperage = kVA / (Voltage x √3). This formula helps ensure accuracy in amperage assessments.

In practical applications, the Transformer Association outlines typical cases. For example, a 100 kVA transformer at 480 volts would have an amperage of roughly 120.6 A. Understanding these standards can prevent errors. Misjudging amperage may lead to equipment failure or safety concerns.

It's also worth noting the importance of temperature ratings. Temperature can affect wire ratings significantly. The American National Standards Institute (ANSI) considers these ratings vital. Many overlook temperature's influence on performance. This oversight can result in inadequate cooling. Such issues might shorten transformer lifespan or create inefficiencies.