Determining the optimal Ct On Transformer is crucial for efficiency. A proper current transformer (CT) ensures accurate measurements. Its function is vital in protecting electrical systems.

Choosing the right Ct On Transformer involves careful analysis. Factors include transformer type, load conditions, and installation requirements. Each variable can significantly impact performance. Ignoring these aspects may lead to inefficient operations or even failures.

Practical issues often arise during this process. Technicians may overlook essential specifications or miscalculate the load requirements. Reflecting on previous installations can reveal common mistakes. Learning from these can enhance future performance. Precision in every detail is key to achieving optimal results.

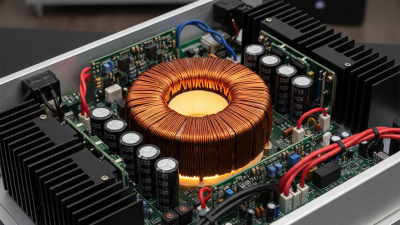

Current transformers (CTs) play a crucial role in electrical systems. They measure current flowing through conductors and provide a scaled-down version for monitoring. This makes them essential for safety and efficiency.

The selection of an appropriate CT is vital for optimal performance. Choosing the wrong ratio can lead to inaccurate readings. This may result in faulty data which can misinform decisions. It's important to analyze current levels carefully before selecting a transformer. A CT can also influence protective relaying and fault detection.

While many focus solely on voltage and power load, neglecting the CT can be detrimental. Properly determining the size and specifications of a CT is not always straightforward. Sometimes, the data from CTs is misinterpreted, leading to further complications. It emphasizes the need for deeper understanding and reflection on their integration into an electrical system.

| Parameter | Value | Unit | Notes |

|---|---|---|---|

| Primary Current | 300 | A | Expected primary current of the transformer |

| Secondary Current | 5 | A | Typical output for protection systems |

| Turns Ratio | 60:1 | - | Ratio between primary and secondary windings |

| Burden | 2.5 | VA | Load on the secondary side of the CT |

| Accuracy Class | 0.5 | - | Level of accuracy at rated current |

| Insulation Level | 24 | kV | Rated voltage for insulation protection |

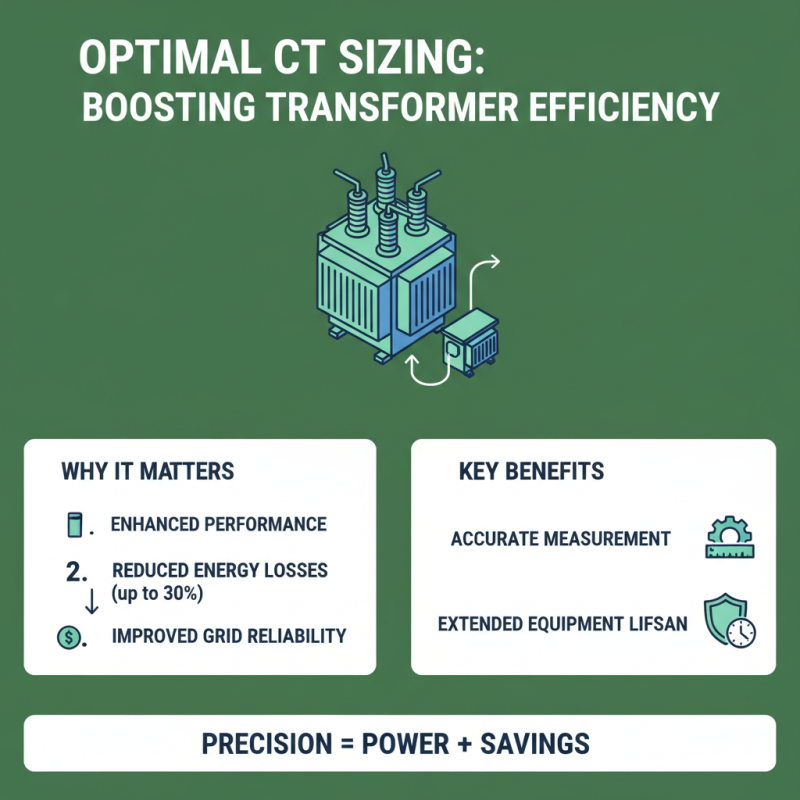

Selecting the appropriate current transformer (CT) rating is critical for optimal transformer performance. Various factors influence this decision. First, the load current in your system plays a significant role. It's essential to estimate the peak load accurately. Industry reports suggest that a mismatch in CT rating can lead to inaccuracies of approximately 10% to 20% in measurement, which could destabilize operations.

Additionally, environmental conditions should not be overlooked. Factors like temperature, humidity, and altitude can affect the performance of CTs. For instance, in high humidity areas, insulation materials may degrade faster, impacting measurement accuracy. Data from various studies indicate that 40% of transformers fail prematurely due to incorrect CT ratings influenced by environmental stressors.

Finally, consider the application. High-speed switching applications demand CTs with precise ratings to avoid saturation. Oversized CTs may miss critical transients. Yet, selecting a CT that is undersized can also lead to significant measurement errors. Reports reveal that around 30% of installations evaluate their CT ratings only at the time of installation, ignoring long-term operational variables. Such oversights can hinder system efficiency.

This chart illustrates the CT Ratios of various transformers, which are critical for optimal performance. The selected CT ratings directly influence the measuring accuracy and operational efficiency of the transformer during its lifecycle.

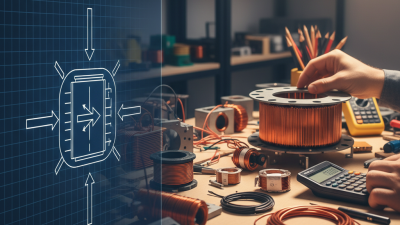

Calculating the optimal current transformer (Ct) for transformer applications is crucial for efficiency. Accurate calculations can enhance performance and reduce losses. According to a recent industry report, transformer losses can account for up to 30% of energy wastage in power systems. Thus, precise Ct sizing directly affects the reliability of the grid.

To begin, identify the primary and secondary currents. Understanding these values is essential. For instance, a transformer with a primary current of 100A may require a Ct with appropriate ratio adjustments. Many engineers recommend a ratio of 100:5 for common applications, ensuring compatibility and safety. Also, consider the burden rating of the Ct, which must align with the connected load.

Another important factor is the accuracy class of the Ct. A report from the International Electrotechnical Commission indicates that using higher accuracy classes can significantly improve measurement precision. However, misuse or miscalculation of parameters can lead to inefficiencies. Small errors might seem negligible but can escalate. It's vital to review calculations and test results thoroughly. Regular audits of Ct installations can also yield insights into performance gaps.

Determining the correct current transformer (CT) rating is crucial for optimal performance. Many engineers make mistakes that can lead to inefficiencies. One common error is miscalculating the primary current. It's essential to accurately measure the current flowing through the transformer. A simple oversight here can result in under or overloading the CT, affecting its lifespan.

Another mistake to avoid is neglecting the application requirements. Not all transformers serve the same purpose. Some are meant for protection, while others are for metering. Selecting a CT without understanding its role can result in poor electrical monitoring. Additionally, the burden resistor must match the current transformer. Ignoring this can cause inaccurate readings and reduce system reliability.

It’s easy to overlook these details in the initial design phase. Many professionals rush the process, thinking they know best. This can lead to long-term operational issues. Always take time to verify specifications and application needs before finalizing any CT. Reassessing existing setups can reveal surprising insights and improve performance significantly.

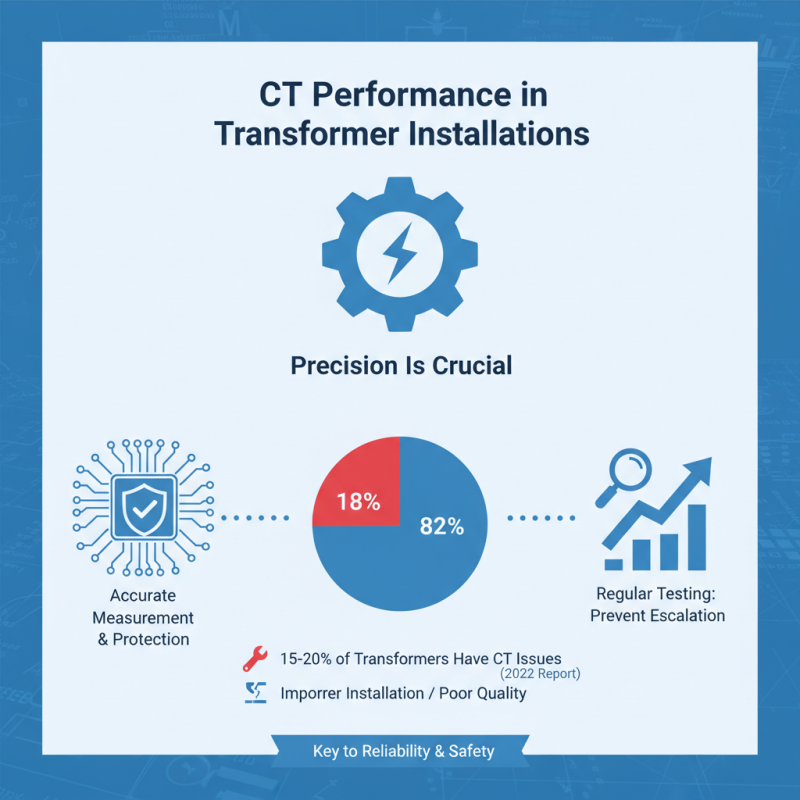

When testing and verifying CT performance in transformer installations, precision is crucial. Current transformers (CTs) are vital for accurate measurement and protection. According to a 2022 industry report, about 15–20% of transformers may have CT issues due to improper installation or poor quality. Regular testing of these components can reveal problems before they escalate.

A common method for verification is ratio testing. This assesses the CT's transformation ratio against specifications. Experts suggest that CTs should have a testing standard of 1% accuracy. Many installations, however, do not meet this benchmark. Third-party testing can help identify discrepancies. Physical inspections looking for signs of wear or damage are critical as well.

Temperature plays a significant role in CT performance. Elevated temperatures can degrade insulation. A recent survey found that 25% of CT failures occur due to overheating. Monitoring systems for temperature variations can prevent these problems. Regular checks and maintenance can enhance CT reliability and longevity.