When embarking on a project that requires structural integrity and durability, the choice of materials becomes paramount. Among these, the Laminated Steel Core has emerged as a preferred solution in industries ranging from construction to manufacturing. According to a recent report by the Steel Institute, the demand for Laminated Steel Cores has surged by 30% in the last five years due to their versatile applications and superior performance advantages, particularly in load-bearing scenarios. This trend highlights the necessity of understanding the different types of Laminated Steel Cores available and their suitability for specific project requirements.

Industry expert Dr. Emily Carter, a leading voice in materials engineering, emphasizes the significance of this choice: "Selecting the right Laminated Steel Core is not just about performance; it's about ensuring the longevity and safety of your entire project." Her insights remind us that a well-informed decision can significantly impact not only the project’s immediate success but also its sustainability over time. As the landscape of material technology continues to evolve, contractors and engineers must remain vigilant and knowledgeable, ensuring that the Laminated Steel Core they choose aligns with their project’s goals and engineering integrity.

When choosing the right laminated steel core for your project, it is essential to understand the various types available and their specific applications. Laminated steel cores can be categorized primarily into types such as standard laminated cores, high-performance laminated cores, and specialty laminated cores. Each type offers unique properties that cater to different requirements, such as electrical efficiency, mechanical strength, or specific environmental conditions.

Standard laminated cores are typically used in general applications, where moderate performance and cost-effectiveness are prioritized. They provide essential magnetic properties while minimizing eddy current losses, making them suitable for applications like transformers and inductors.

In contrast, high-performance laminated cores are designed for applications demanding superior efficiency and reduced losses, often utilized in advanced electrical devices like high-frequency transformers and electric motors.

Specialty laminated cores, on the other hand, have specific attributes, including heat resistance or moisture resistance, which makes them ideal for unique environments or specific industrial applications. Understanding these core types and their respective strengths will help guide your decision-making process in selecting the most appropriate laminated steel core for your project's needs.

When selecting a laminated steel core for your project, several critical factors come into play. First and foremost, the intended application dictates the performance requirements of the steel core. For instance, solutions designed for high-stress environments, such as automotive or aerospace industries, often require cores with enhanced strength and fatigue resistance. According to a recent industry report from the Steel Association, laminated steel cores used in automotive applications can improve impact resistance by up to 30%, highlighting the importance of material selection that aligns with specific mechanical demands.

Another vital consideration is the thickness and configuration of the laminations. Studies have shown that varying the thickness of the laminations can significantly affect not only the performance but also the cost efficiency of the final product. Laminations that are too thick may result in unnecessary weight, potentially impacting the overall functionality. The optimal configuration is often found through a balance between performance requirements and production costs; data from a leading materials research institute indicates that projects utilizing precise lamination configurations can achieve a reduction in material waste by up to 15%, which is an essential factor for sustainable manufacturing practices.

Lastly, electromagnetic properties should not be overlooked, especially in applications like transformers and electrical motors. The laminated steel core’s ability to minimize eddy current losses is directly influenced by its material composition and geometry. Recent findings published in the Journal of Electrical Engineering emphasize that using high-quality silicon steel laminations can decrease energy losses by approximately 20%, making it crucial to evaluate the electrical characteristics alongside mechanical properties for optimal efficiency.

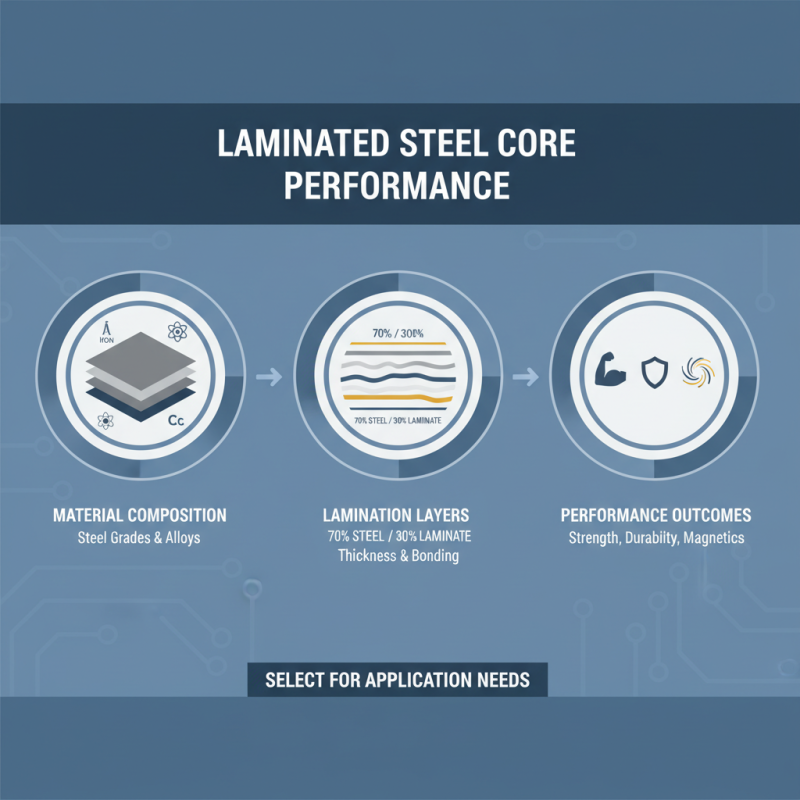

When evaluating the performance characteristics of laminated steel cores, several factors come into play which can greatly influence the outcome of your project. One of the most critical aspects to consider is the material composition and the layers involved in the lamination process. Different combinations of steel grades and laminate thicknesses can yield varying levels of strength, durability, and magnetic properties. Understanding these aspects will help you select a laminated steel core that meets the specific needs of your application.

Tips: Before making your selection, it is advisable to consult with a materials engineer who can provide insights based on your project's requirements. They can help you assess load-bearing capacities and compatibility with existing systems. Additionally, always refer to material specifications provided by manufacturers to ensure you’re considering all relevant characteristics such as thermal conductivity and resistance to fatigue.

Another important performance characteristic is the core's impact resistance. Laminated steel cores often exhibit enhanced toughness due to their layered structure, making them less susceptible to fracturing under stress. It's essential to analyze the expected operational environment and consider factors like pressure and temperature extremes that may affect core performance. Testing the core under conditions that mirror its eventual use can provide valuable data, ensuring it can withstand the demands of your project.

Tips: Conducting preliminary tests or simulations can save time and resources later while also ensuring that you’re making an informed choice based on empirical data.

When selecting the right laminated steel core for your project, understanding the cost and durability aspects of various laminated steel options is crucial. According to a recent industry report by Smith & Associates, the average cost per square foot for laminated steel can range from $30 to $60, largely influenced by the manufacturing processes and the thickness of the lamination used. High-quality laminated steel, although more expensive upfront, often offers better resistance to wear and tear, as well as environmental stressors, making it a more economical choice in the long run.

Tip: When evaluating costs, consider the total lifecycle expenses of the steel, including not just the initial purchase price but also maintenance and replacement costs. For example, projects utilizing laminated steel with higher tensile strength may have a lower frequency of required repairs, ultimately saving money over time.

Durability is another essential factor, as laminated steel cores are designed to perform under extreme conditions. According to the Steel Construction Institute, laminated steel typically has a yield strength of 250 MPa to 800 MPa, allowing it to withstand significant stress. Choosing a laminated steel option that meets or exceeds your specific project requirements can significantly enhance the longevity and integrity of the construction.

Tip: Always compare the specifications of laminated steel options by reviewing their performance data and certifications to ensure they align with your project’s needs. This practice not only helps in navigating the plethora of choices but also in securing a material that will stand the test of time.

| Type of Laminated Steel | Cost per Square Foot | Durability Rating (1-10) | Weight (lbs/sq ft) | Best Applications |

|---|---|---|---|---|

| Standard Laminated Steel | $8.00 | 7 | 2.5 | General construction |

| High-Strength Laminated Steel | $10.50 | 9 | 3.0 | Industrial applications |

| Galvanized Laminated Steel | $12.00 | 8 | 2.8 | Outdoor structures |

| Composite Laminated Steel | $15.00 | 10 | 2.2 | Aerospace and military |

| Fire-Resistant Laminated Steel | $18.00 | 9 | 2.6 | Fire safety structures |

When integrating laminated steel cores into your project, one of the best practices is to start with a thorough understanding of the specific requirements of your application. Consider factors such as load-bearing capacity, environmental conditions, and dimensional stability. Conducting a detailed assessment will help you decide the appropriate thickness and composition of the laminated steel core, ensuring that it meets performance standards while maintaining structural integrity.

Additionally, maintaining precise alignment during the installation process is crucial for optimal performance. Misaligned cores can lead to structural weaknesses and compromise the entire project. Using proper fastening techniques and ensuring that all components are securely bonded will enhance the overall durability and effectiveness of the laminated steel core. Regular inspection and maintenance of these elements will further prevent potential issues and extend the lifespan of your project, ensuring everything operates as intended.

This bar chart illustrates the performance metrics of different laminated steel core types based on tensile strength, corrosion resistance, and thermal conductivity.