In recent years, the construction and manufacturing industries have increasingly recognized the critical role of materials that combine strength with versatility. One such material gaining traction is the Laminated Steel Core, which offers a unique blend of durability and lightweight properties, essential for a variety of projects. According to a report from the Global Steel Innovation Forum, the demand for laminated steel products is projected to grow by 8% annually through 2025, as architects and engineers seek solutions that enhance structural integrity while reducing overall weight.

The versatility of Laminated Steel Core has made it a favored choice for applications ranging from automotive parts to advanced architectural elements. Its engineered composition not only empowers better load-bearing capacity but also allows for innovative design possibilities. Moreover, a comprehensive analysis by the International Journal of Structural Engineering indicates that projects utilizing Laminated Steel Core can achieve significant cost savings in both material and labor—potentially reducing project timelines by up to 15%. Given these advantages, understanding the essential factors in selecting the appropriate Laminated Steel Core for your specific projects will be crucial in capitalizing on this material’s benefits.

Laminated steel core is an increasingly popular material choice in various industries due to its unique properties and versatile applications. Defined as a composite material made by layering thin sheets of steel, laminated steel core offers improved structural integrity and enhanced performance characteristics. According to recent market analysis by industry experts, the global laminated steel market is projected to grow at a compound annual growth rate (CAGR) of 5.3% from 2023 to 2028, driven by rising demand from the automotive and construction sectors, which increasingly rely on advanced materials for efficiency and strength.

In terms of applications, laminated steel core is particularly beneficial in electrical and mechanical fields. Its use in transformers and inductors is noteworthy, as it minimizes energy losses due to eddy currents, improving energy efficiency. A report by the International Electrotechnical Commission highlights that the adoption of laminated cores in electrical devices can reduce losses by up to 30%, underscoring its significance in energy-sensitive applications. Furthermore, laminated steel’s lightweight properties make it an ideal candidate for advanced vehicular designs, where weight reduction is critical for performance and fuel efficiency.

Overall, laminated steel core stands out for its balance of strength, weight, and electrical performance, making it a preferred choice across diverse engineering and manufacturing applications. The ongoing advancements in material technology are likely to further enhance its capabilities, solidifying its position as a key component in future projects.

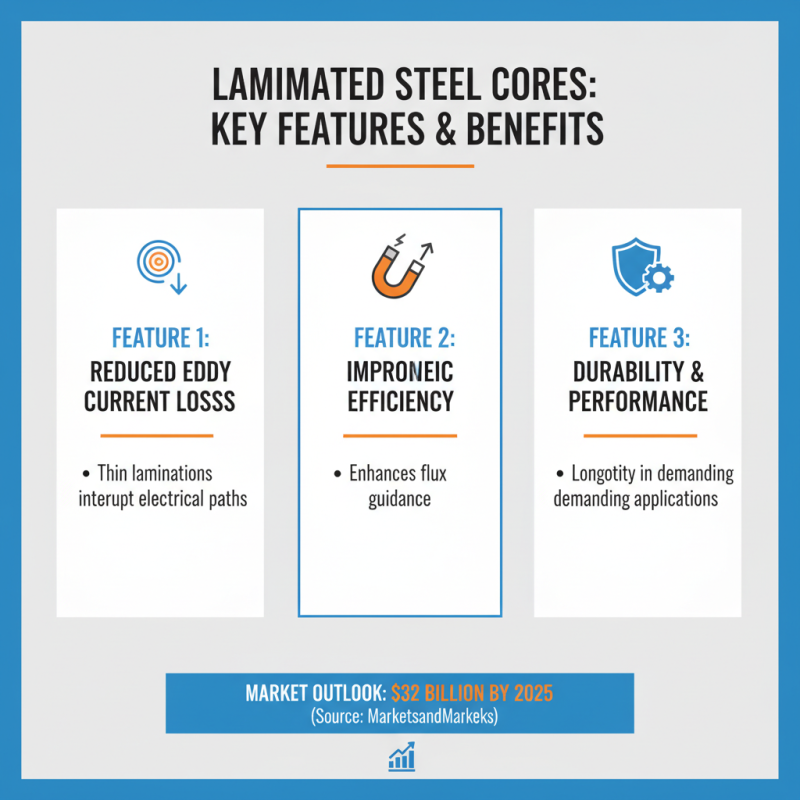

When selecting laminated steel cores for your projects, it's essential to understand their key features to ensure optimum performance and durability. Laminated steel cores are engineered to reduce eddy current losses and improve magnetic efficiency, making them a choice for high-performance applications. According to a recent industry report by MarketsandMarkets, the laminated steel market is expected to reach USD 32 billion by 2025, highlighting the growing importance of quality core materials in various industries.

One critical feature to consider is the thickness of the laminations; thinner layers often lead to reduced energy losses. Standard thicknesses can range from 0.35mm to 0.5mm, affecting the overall efficiency of the magnetic circuit. Moreover, the material's insulation properties play a significant role in preventing short circuits and enhancing the core's operational lifespan. The right insulation can increase efficiency by up to 10%, as noted in a 2022 research study by the International Journal of Electrical Engineering.

Tips: When assessing laminated steel cores, always request detailed specifications and samples to evaluate their magnetic and thermal performance. Additionally, consider the manufacturing standards, as these can significantly impact the quality and reliability of the cores. Investing in high-quality laminated steel cores will lead to better long-term outcomes for your projects, ensuring they run smoothly and efficiently.

When considering laminated steel for various projects, it's essential to evaluate the pros and cons of different types. For instance, laminated steel with a higher core thickness often provides enhanced durability and resistance to deformation under heavy loads. This type is generally suited for structural applications where strength is paramount. However, the increased weight can be a downside in certain projects where maintaining a lightweight structure is crucial. Additionally, the cost of thicker laminated steel tends to be higher, which could impact budget considerations.

On the other hand, thinner laminated steel options can offer greater flexibility and are often easier to handle and install. These types may be more cost-effective and suitable for applications where extreme strength isn't as critical. However, the trade-off might be a reduction in long-term durability and potential susceptibility to damage from external stresses. Therefore, it's important to assess the specific requirements of your project, weighing the need for strength against factors like weight and budget, to make an informed choice on the best laminated steel core for your needs.

When sourcing high-quality laminated steel cores for your projects, it's crucial to consider factors such as material composition, thickness, and the manufacturing process. Quality is paramount since the performance of your projects heavily relies on the durability and strength of the steel core. Look for suppliers that provide certifications or test results demonstrating their materials can withstand the rigors of your intended application.

Tips: Always ask about the sourcing of raw materials. High-quality laminated steel should ideally be made from virgin metals, which ensure better performance compared to recycled materials prone to impurities.

Additionally, pay attention to the lamination process. A well-executed lamination improves magnetic properties and reduces eddy currents, enhancing efficiency. Suppliers should be able to explain their lamination methods and the benefits they bring to the final product.

Tips: Don't hesitate to request samples before making a bulk purchase. Inspecting the samples for consistency in thickness and finish can save you from potential pitfalls and ensure that the final product meets your expectations.

| Property | Description | Importance | Recommended Values |

|---|---|---|---|

| Thickness | The physical thickness of the laminated steel core. | Influences strength and durability. | 0.5 - 5.0 mm |

| Material Grade | Grade of steel used for laminating. | Affects performance under stress. | ASTM A1008, AISI 1010 |

| Surface Finish | Finish applied to the surface of the core. | Improves corrosion resistance. | Galvanized, Coated |

| Coating Type | Type of coating used to enhance properties. | Critical for environmental resistance. | Epoxy, Polyester |

| Temperature Resistance | Ability to withstand heat without degrading. | Essential for high-temperature applications. | Up to 250°C |

| Standard Compliance | Adherence to industry standards and certifications. | Guarantees quality and safety. | ISO 9001, ASTM |

When selecting laminated steel cores for projects, many professionals tend to overlook critical factors that can greatly impact performance and longevity. One common mistake is underestimating the importance of load-bearing capacity. According to a report by the Steel Construction Institute, improper load analysis can lead to a 30% reduction in structural integrity over time. Therefore, it is essential to consider not only the expected load but also possible environmental factors that could affect performance.

Another frequent pitfall is neglecting the selection of adhesives used in laminated steel. A study from the Composite Materials Handbook indicates that the choice of adhesive can significantly affect the overall durability of the laminated structure, with some adhesives providing only half the longevity of others. This emphasizes the need for comprehensive evaluation of both the steel and the materials used to bond the layers. Thus, taking the time to research and select appropriate adhesive solutions is crucial for the success of any project involving laminated steel cores.